Images & Logos

Download Image

H.E Orr’s expansion will allow the Tier One wire-forming and coating firm to better serve North America’s largest automobile manufacturers by increasing production capacity and parts production flexibility and fulfillment. The expansion will add four, full-time employees and one flex-temp to the H.E. Orr team bringing the total employment to 62 team members.

Download Image

H. E. Orr’s equipment list allows near instant production of any part, whenever needed, in quantities from five to fifty thousand, in size ranges from 3mm high tensile to 12mm mild steel. The company offers multiple variations in one run with no tooling changes and the highest overall production speeds in the industry. Short lead times and low tooling costs also guarantee success.

Download Image

Herbert E. Orr Company completed a 12,000 square foot expansion of its manufacturing headquarters in Paulding, Ohio. The 20 percent expansion enhances the existing facility from 60,000 to 72,000 square feet. The expansion allows the Tier One wire-forming and coating firm to better serve North America’s largest automobile manufacturers by increasing production capacity and parts production flexibility and fulfillment. The expansion will add four, full-time employees and one flex-temp to the H.E. Orr team bringing the total employment to 62 team members.

Download Image

H.E. Orr is one of the few wire forming and forging operations in the nation to perform e-coating and powder coating in one continuous line. The new plant expansion serves as part of another consolidation strategy, moving the operations of nine additional wire bending machines in-house from services that were formerly contracted from Tier Two suppliers.

Download Image

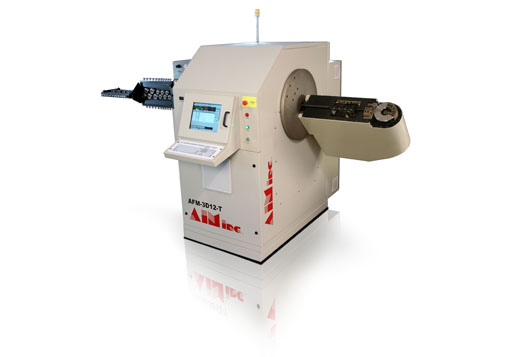

The addition of the AIM 3D-12T CNC wire forming machine to H. E. Orr’s equipment list allows near instant production of any part, whenever needed, in quantities from five to fifty thousand, in size ranges from 3mm high tensile to 12mm mild steel.

Download Image

H.E. Orr’s new CNC wire forming machine, with up to 32 axis motion, takes wire directly from a coil, straightens it, bends it, and cuts it to create any profile needed with minimal tooling changes.

Download Image

The addition of the AIM 3D-12T CNC wire forming machine to H. E. Orr’s equipment list allows near instant production of any part, whenever needed, in quantities from five to fifty thousand, in size ranges from 3mm high tensile to 12mm mild steel.

Download Image

Test plates are cross-hatched to test corrosion resistance to areas near damage.

Download Image

Multiple styles of parts moving via conveyor system.

Download Image

Wheel wrenches from H.E. Orr’s forging operation are being painted in the E-coat bath.

Download Image

Salt-spray fog disperses when the chamber is opened.

Download Image

Test plates are hung in the chamber for testing.

Download Image

Extensive testing takes place throughout the coating process.

Download Image

Logo JPEG.

Download Image

Logo Adobe Illustrator File.